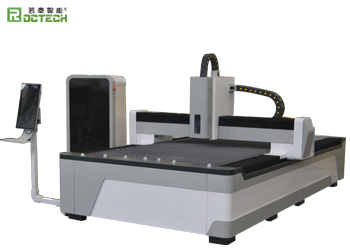

We know that an important indicator for measuring the quality of a laser processing machine is its machining accuracy. The processing accuracy of ROCLAS laser processing machine can reach an incredible 0.01mm! Today we will analyze how the ROCLAS laser processing machine achieves such high precision.

The first reason is that the ROCLAS laser machine adopts a high-precision mechanical structure.

The ROCLAS laser machine adopts a high-strength steel pipe structure, which has undergone tempering and stress relief treatment to maximize the strength of the bed body. Ensure that the equipment remains stable during high-speed operation to avoid the impact of vibration on machine accuracy. High precision guide rails and ball screws. The machine adopts imported high-precision guide rails and ball screws, with low friction coefficient, stable operation, and long service life, ensuring the accuracy of the machine during high-speed motion. Using imported servo motors and reducers, the response speed is fast, there will be no step loss, and the machine can be operated accurately.

The second reason is that the ROCLAS laser machine has an advanced control system. The ROCLAS laser processing machine automatically optimizes cutting parameters for material thickness and has the functions of automatic edge search and automatic focusing. Its servo motor adopts closed-loop control. This type of motor can monitor the position and motion status of the machine in real time. This ensures stability and accuracy during the cutting process.

The third reason is that the ROCLAS laser machine uses a MAX laser source. This laser source has good beam quality, small focal spot, and can achieve finer cutting. And its power output is stable, reducing the impact of power fluctuations on laser accuracy. By using a cooler, the temperature of the laser is effectively controlled to ensure long-term stable operation of the laser.

The fourth reason is that the ROCLAS laser machine undergoes strict quality control before leaving the factory. All parts of the ROCLAS laser machine are processed by precision machining centers. Its quality is strictly controlled during the production process. All machines undergo strict testing before leaving the factory and have good performance.

In summary, the ROCLAS laser machine can achieve a processing accuracy of 0.01, which cannot be achieved without the pursuit of excellence in every design, manufacturing, and monitoring process. All of this is aimed at satisfying users. The outstanding performance of every ROCLAS laser machine is the honor of ROCLAS company. If you are interested in the ROCLAS laser machine or would like to learn more details, please feel free to contact us at any time. We would be honored to answer any questions related to this machine for you. ROCLAS can provide you with various production solutions. We look forward to you contacting us!

Looking for more information about our CNC machines and services? Contact us today.

Contact

Previous:Why Do I Recommend ROCTECH CNC Engraving Machine

Next:What Woodworking Industries Can CNC Engraving Machines Be Used In?