Firstly, we need to understand that laser cutting machines have very high precision and efficiency. If you want to purchase a cutting machine, laser cutting machine is currently a popular choice.

Secondly, the choice of laser machine depends on the type of raw materials you process. Is the raw material you want to process metal (carbon steel, stainless steel, aluminum alloy, copper, etc.) or non-metal (acrylic acid, cardboard, etc.)? Is the raw material you need to process thick or thin? Do you need cutting, carving, marking, or welding as the processing technology? Is the machining accuracy you require high or average? Before purchasing a laser machine, you need to clarify these processing requirements so that you can use them as a goal to find the most suitable machine for you.

For example, if you want to cut metal materials such as stainless steel, carbon steel, copper, aluminum alloy, etc., you must choose a high-power fiber laser cutting machine. If you want to cut non-metallic materials such as acrylic, cardboard, etc., you can choose a CO2 laser engraving machine. If you want to weld, mark, clean and other metals, you should choose laser welding, marking machines, etc.

Thirdly, after understanding your processing requirements, experienced manufacturers will select suitable machines for you based on your specific needs and budget, and make corresponding configurations. The configuration of a laser machine includes laser power, worktable, processing accuracy, and whether there are any additional requirements.

The laser power determines the cutting ability of the machine. The greater the power, the stronger the cutting ability, and the higher the thickness that can be cut, but the price will also increase accordingly. Therefore, the higher the power, the better. The machine that suits your factory's processing needs is the good machine.

The workbench depends on the size of the material we are processing. We generally recommend choosing a table slightly larger than the processing material to meet the potential for larger processing requirements in the future. Generally speaking, the countertop can be larger, not smaller.

In addition, the processing accuracy determines the precision of the processed product. If you have high precision requirements for the product, you must choose high-precision machines. If you have other personalized processing requirements, they need to be customized according to your needs.

Fourthly, you should pay attention to the after-sales service provided by the manufacturer. Because laser machines are precision machines, installation, debugging, and maintenance all require services provided by manufacturers, so after-sales service is crucial. When choosing a machine manufacturer, you should choose a manufacturer or service provider with comprehensive after-sales service to solve any problems encountered during machine use at any time.

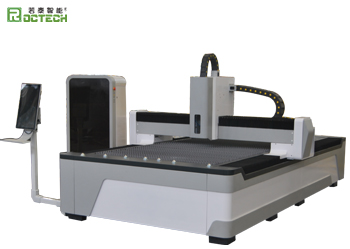

Finally, we would like to recommend the ROCLAS laser machine to you, which has reliable quality and first-class service. We can provide you with one-stop service. If you have any questions about the laser machine, please feel free to consult us at any time. We have a professional team that can provide you with detailed answers to various questions about the machine. You can also leave us a message on the website or send us an email. You can tell us your needs, and we will provide you with solutions for you to choose from. We are dedicated to serving you and look forward to hearing from you.

Looking for more information about our CNC machines and services? Contact us today.

Contact