In furniture making and woodworking creative design, CNC engraving machines have become an indispensable role. Whether it is a furniture manufacturer or a woodworking DIY enthusiast, a suitable engraving machine can make you more powerful. So how to choose a machine that suits you?

1. Clear needs

First of all, before choosing an engraving machine, you must first clarify what you want to do with this engraving machine, whether it is for professional production or to make some handicrafts yourself. Different usage scenarios determine the selection criteria of the equipment. If it is used for professional production, a large table, high precision, and high power equipment is usually selected. Personal creation pays more attention to the convenience of operation and cost-effectiveness. Therefore, before purchasing, you must clarify your own needs, which is directly related to the power configuration, work surface, and functional characteristics of the equipment.

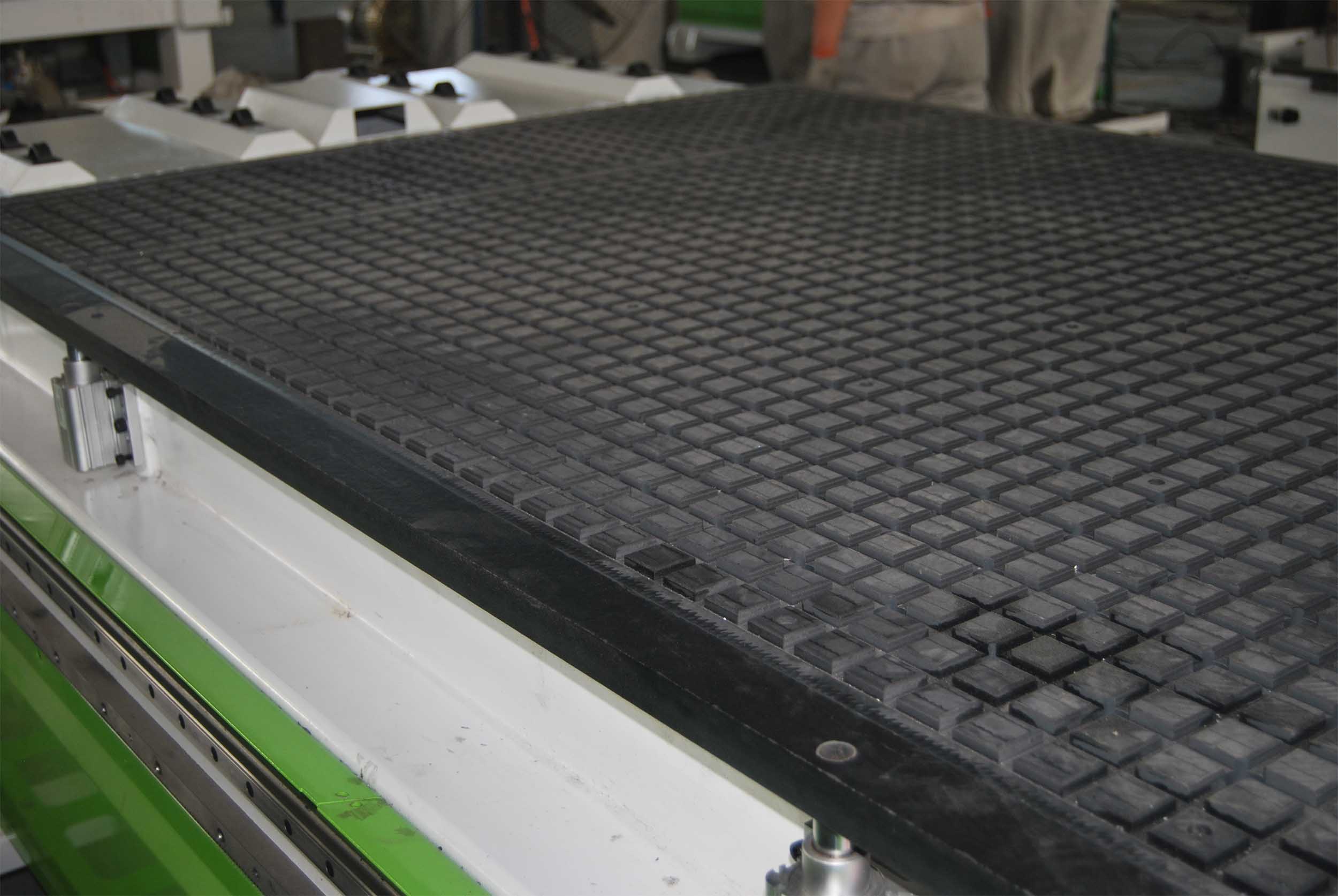

2. Work surface

The size of the work surface is one of the key factors to consider when choosing an engraving machine. It directly determines the size range of materials that the equipment can process. The appropriate work surface size should be determined according to the size of the daily processing board. You can choose a slightly larger table when choosing to cope with the processing needs of larger sizes that may appear in the future.

3. Power

The power determines the strength of an engraving machine, which depends on the hardness of the plate you are cutting. The harder the plate, the greater the power required to cut. Otherwise, the processing will be difficult, and even damage the machine, reducing the service life of the machine.

4. Accuracy

The accuracy of the engraving machine determines the fineness of the cutting. Generally speaking, the engraving accuracy of the CNC engraving machine can meet most of the engraving needs. If you have high requirements for processing accuracy, you can choose a servo motor. If the requirements for accuracy are general, you can choose a stepper motor.

5. Control system

The control system is equivalent to the brain of a machine, and the movement of the engraving machine is all controlled by the operating system. The price, function, and supported software of each control system are different. High-end control systems have more powerful functions, while entry-level operating systems are known for their practicality and cost-effectiveness. At the same time, you should also consider the compatibility of your commonly used design software with the system. Customers need to choose a control system that suits them based on their actual situation.

6. After-sales service

Try to choose an engraving machine from a well-known brand as much as possible, which will not only ensure quality, but also provide more complete after-sales service. Before purchasing, you should understand the warranty period, maintenance services and technical support of the machine to ensure that you can use the machine without any worries.

As a professional engraving equipment manufacturer, ROCTECH can understand that each customer's processing needs are unique. We provide a full range of customized services, from equipment configuration to function optimization, which will be accurately matched according to your specific application scenario, production scale and budget range. Whether you are looking for efficient mass production solutions or need special process customization, our professional technical team will tailor the most suitable engraving equipment for you. Please feel free to contact us. ROCTECH will provide you with professional consultation and the best solution with rich industry experience and perfect after-sales service system.

Looking for more information about our CNC machines and services? Contact us today.

Contact

Previous:How about ROCTECH 5-Axis CNC Router Machine?

Next:ROCTECH Intelligent CNC ROUTER machine: Digital innovation tool to reshape traditional crafts