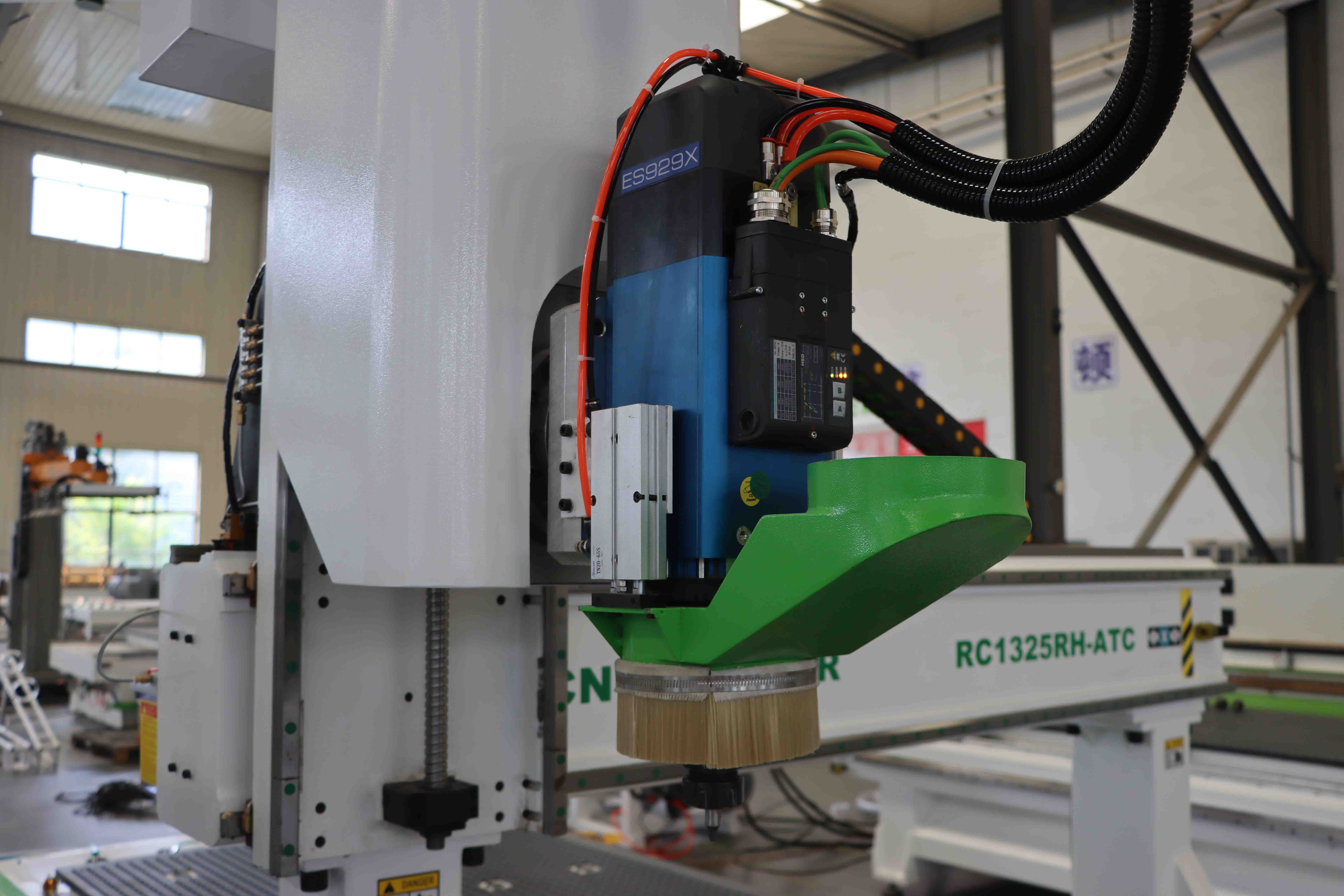

In the production process of some furniture and woodworking crafts, ordinary three-axis CNC engraving machines are difficult to meet the needs of engraving complex curved surfaces. The four-axis CNC engraving machine has an additional rotating axis, which allows the spindle to rotate ±90°, so that it can complete more delicate and multi-angle engraving, which is suitable for the processing of complex three-dimensional patterns and curved surface structures. Today, I will introduce to you a four-axis CNC engraving machine RC1325RH-ATC from ROCTECH.

The machine body adopts a large square tube bed, which has high strength and stability. During the machine processing, it can effectively reduce vibration and improve processing accuracy.

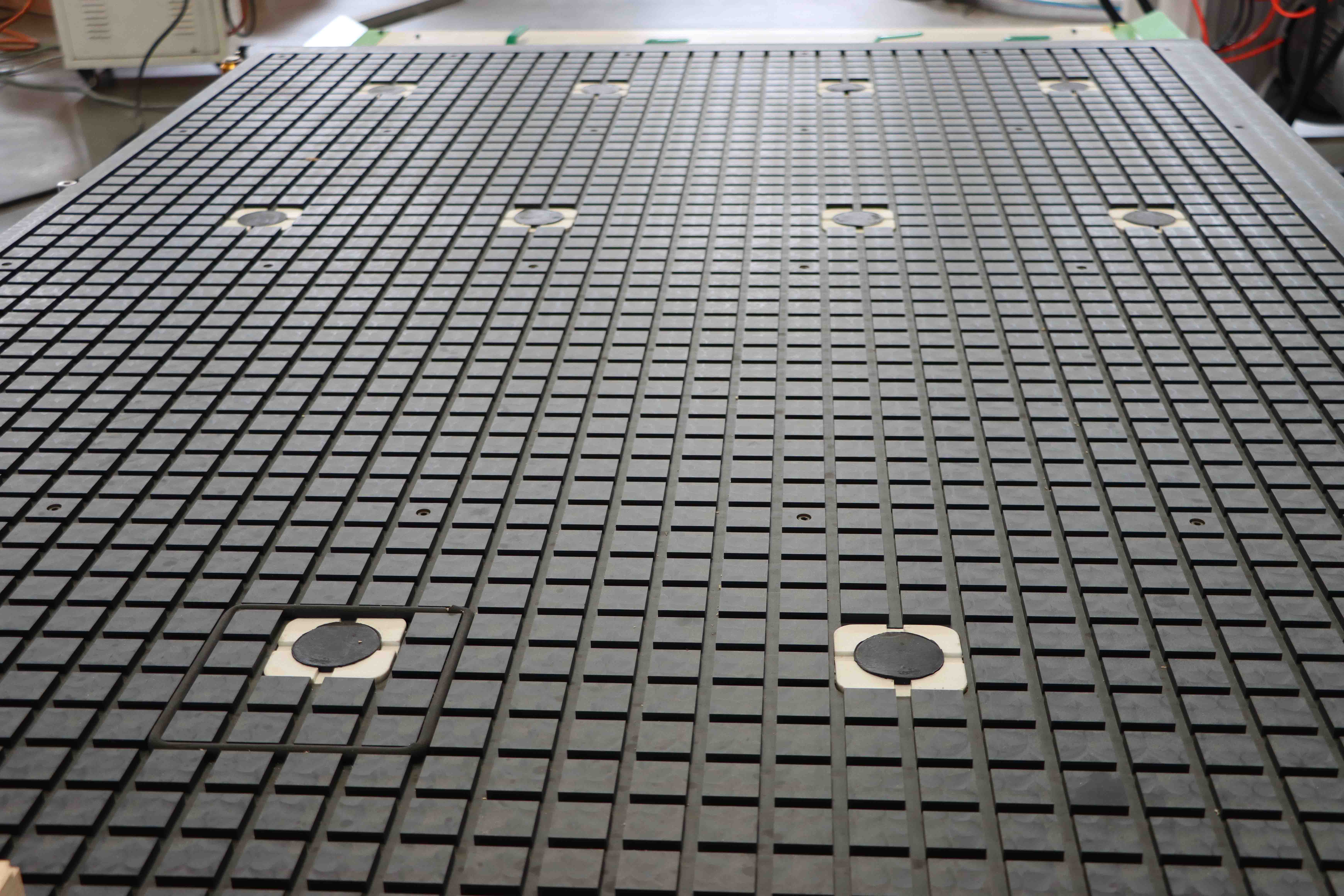

The machine table adopts a vacuum adsorption table to ensure that the plate will not shift during the processing of the machine. We also have a table with T-slots and vacuum adsorption to meet various processing needs. The table size can be determined according to the application scenario of the machine and the size of the processing material. It can meet the engraving of crafts and the processing needs of large molds and plates.

The machine spindle adopts imported HSD 9kw tool change spindle, which has high reliability and high precision. It can complete the tool change action in a short time, greatly shortening the non-processing time. The machine adopts the carousel change system that can hold 12 tools to meet various engraving needs.

The machine is equipped with The Taiwan Syntec control system. The system adopts a graphical user interface. The operator can intuitively view the various parameters of the machine, and the operation is simple and fast. It can accurately control the movement of the four axes. At the same time, the new generation control system has good stability and reliability, reducing downtime caused by failures.

The drive motor on the machine adopts Yaskawa servo motor. It has a high response speed and can quickly start, stop, and change the motion state to improve production efficiency. The power output is strong and can meet the needs of high load and high-speed movement.

The machine adopts imported ball screws and guide rails, which are smooth in transmission and increase the service life of the machine. With imported servo motors, the positioning accuracy and repeatability of the machine can reach ±0.01mm, realizing nano-level precision engraving, ensuring the precise size of the processed products, and meeting the needs of high-precision processing.

In addition, we have an experienced technical team to provide users with all-round technical support, which can be customized according to different needs of customers. At the same time, we have a complete after-sales system, which can provide customers with long-term parts supply and maintenance services, ensuring that users have no worries when using the machine.

For more detailed information about the machine, please visit our official website, where we will provide you with professional technical support and customized solutions.

Looking for more information about our CNC machines and services? Contact us today.

Contact