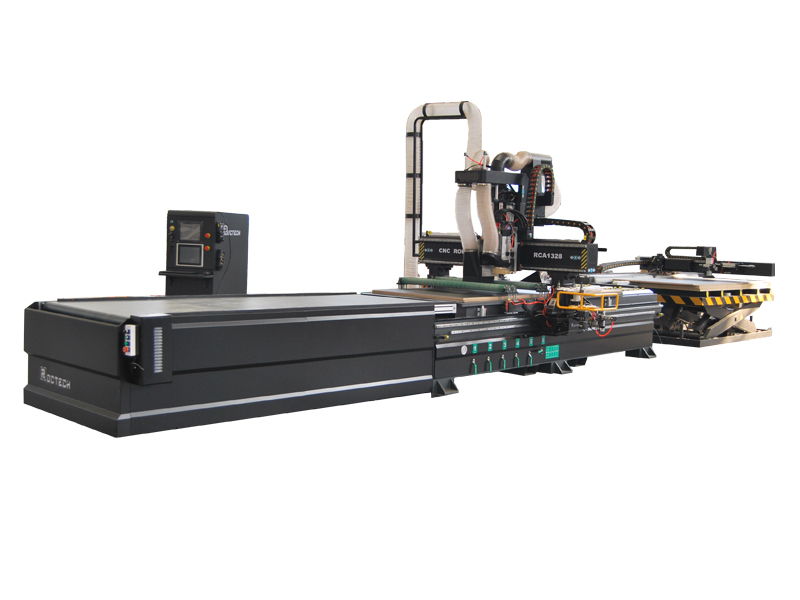

In the panel furniture production line, Auto feeding and nesting center with auto labeling is the most important link. One machine can realize labeling, loading, cutting, unloading and other functions. Just put the plate on the loading platform, and the system will automatically complete the labeling, loading, cutting and unloading actions. Compared with the traditional CNC engraving machine, it greatly improves the production efficiency and saves labor. Here I will introduce ROCTECH's automatic labeling loading and unloading processing center RCA1328-ATC.

The machine adopts Taiwan's Syntec control system. The system adopts a graphical user interface. The operator can intuitively view the various parameters of the machine, and the operation is simple and fast. At the same time, the Syntec control system has good stability and reliability, reducing downtime caused by failures.

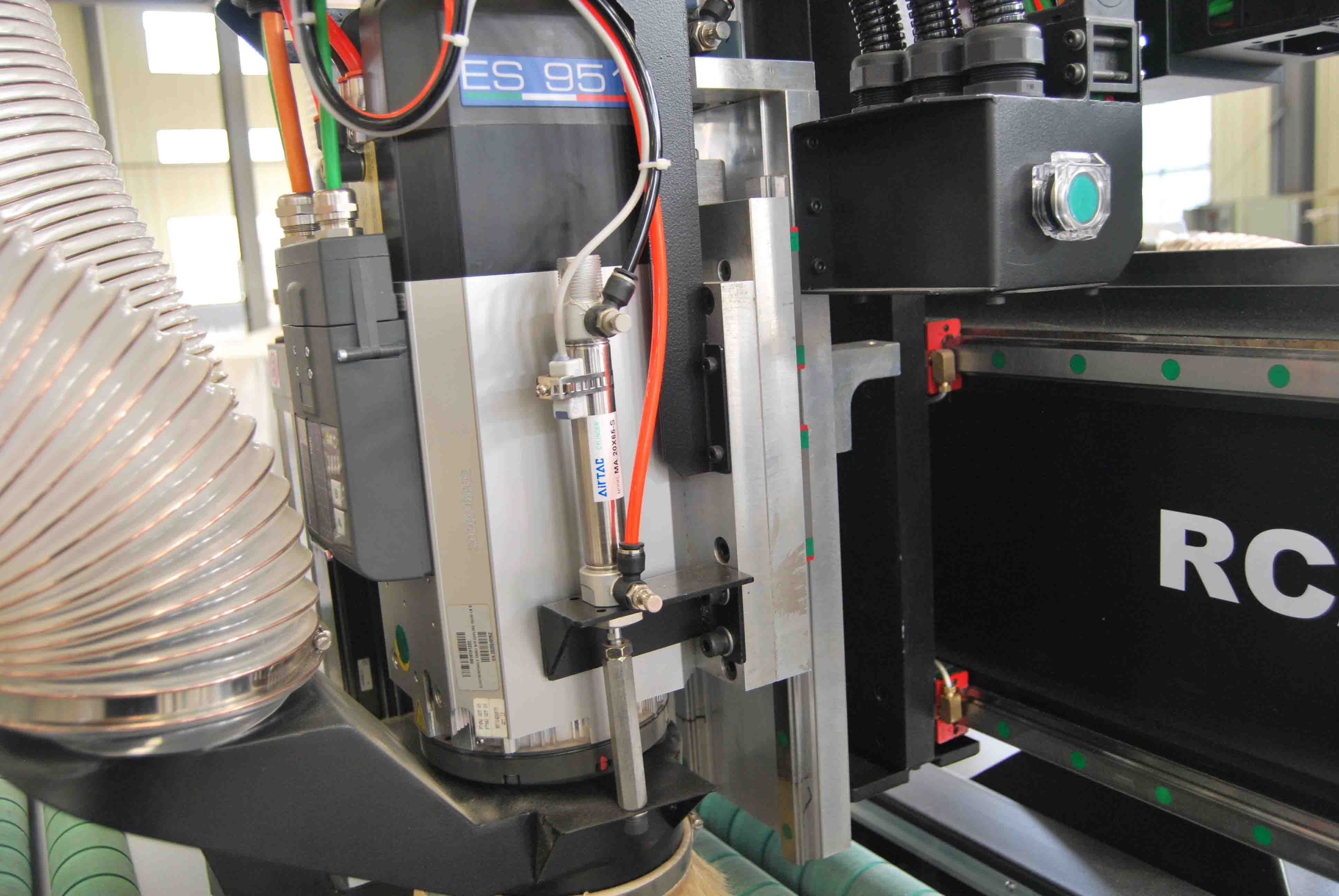

The machine is equipped with HSD tool change spindle and HSD5+4 boring unit. There are 8, 12, and 16 tools for you to choose from, which can meet the drilling and cutting needs of various sizes. The Italian HSD tool change spindle has the characteristics of high precision and high speed, which can achieve high-precision processing, fast tool change speed, save processing time, shorten processing cycle and improve production efficiency. It can also be matched with different combinations according to your needs, and you can also install saw blades for processing.

The drive motor on the machine adopts Yaskawa servo motor. It has high response speed and can quickly start, stop, change motion state, and improve production efficiency. The power output is strong and can meet the needs of high load and high-speed movement.

The whole material function adds a whole material cylinder to the machine body, and the whole material is automatically filled after loading without manual adjustment.

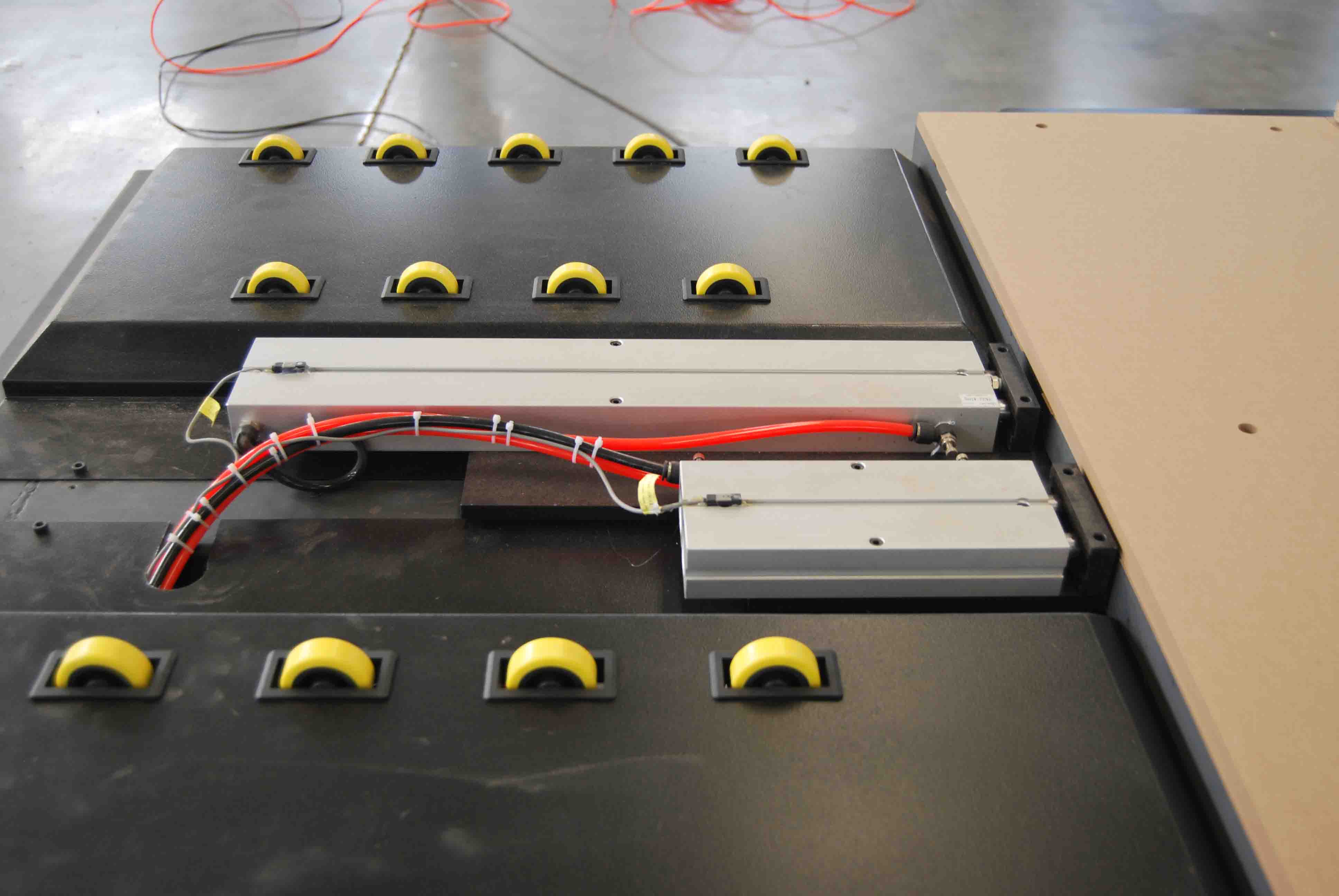

The machine adds a pressing roller on the basis of the vacuum adsorption table to further fix the plate during the processing process, and the plate of any size will not be displaced when processing.

Automatic loading and unloading platform, the customer only needs to put the plate on the loading platform. After the labeling machine labels, the machine grabs the plate and moves the plate onto the table. The loading platform automatically raises the next plate to the corresponding height. During the machine cutting process, the labeling machine can label synchronously to improve processing efficiency. After the plate is cut, the machine pushes the cut plate to the unloading platform. When the conveyor belt of the unloading platform runs to the end, it will be sensed by the infrared device, and the conveyor belt will stop running and wait for the staff to unload.

The machine can be equipped with an additional light curtain protection system. When the machine is running, when a person enters the range of the machine, the machine will automatically stop running and issue a warning to protect the safety of the personnel.

If you are interested in this machine, you can visit our website to contact us.

Looking for more information about our CNC machines and services? Contact us today.

Contact