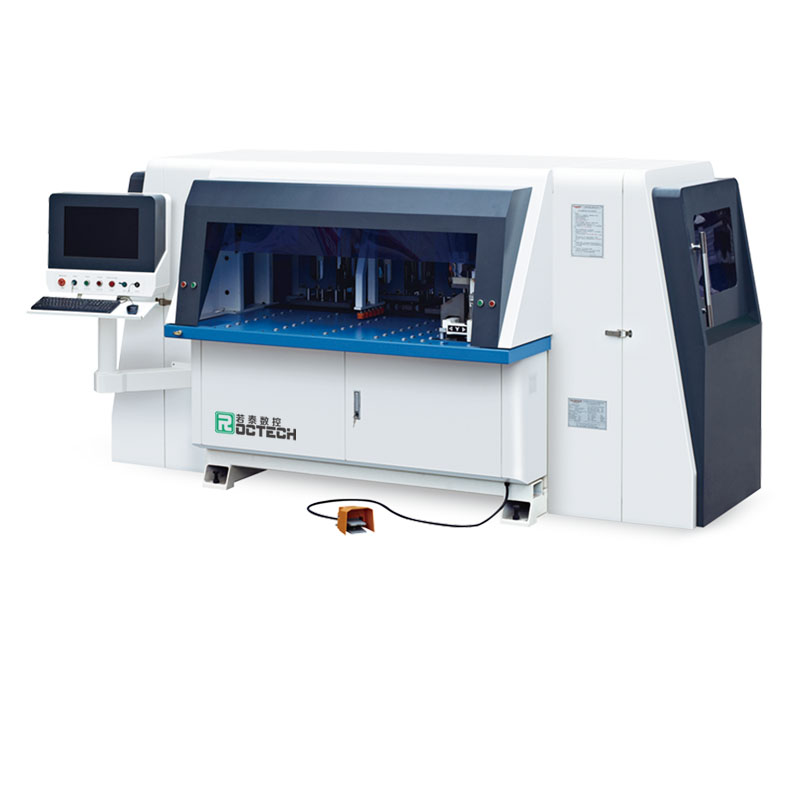

1.The machine is equipped with a 19-inch color screen, wireless keyboard and USB port;The control system is from Japan. The screen can input image and text. It’s very easy to operate;The file format can be designed according to the customer’s production management without drill holes data input. It improves the efficiency of drilling.

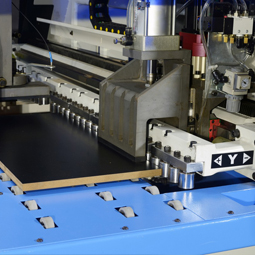

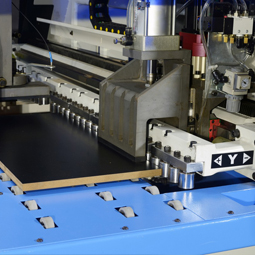

2.Automatic fixing device:It is able to automatically fixed or release the material according to the programming, during the drilling and loading material.

3.Automatic Pop-Up position device,It can automatically locate the material’s positioning, according to different size of work piece.

4.Automatic loading device:It is able to put the sheet to the exact positions which be programmed.

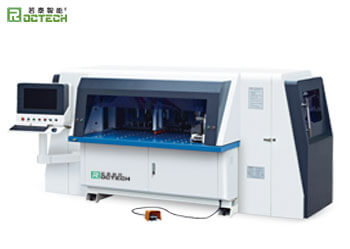

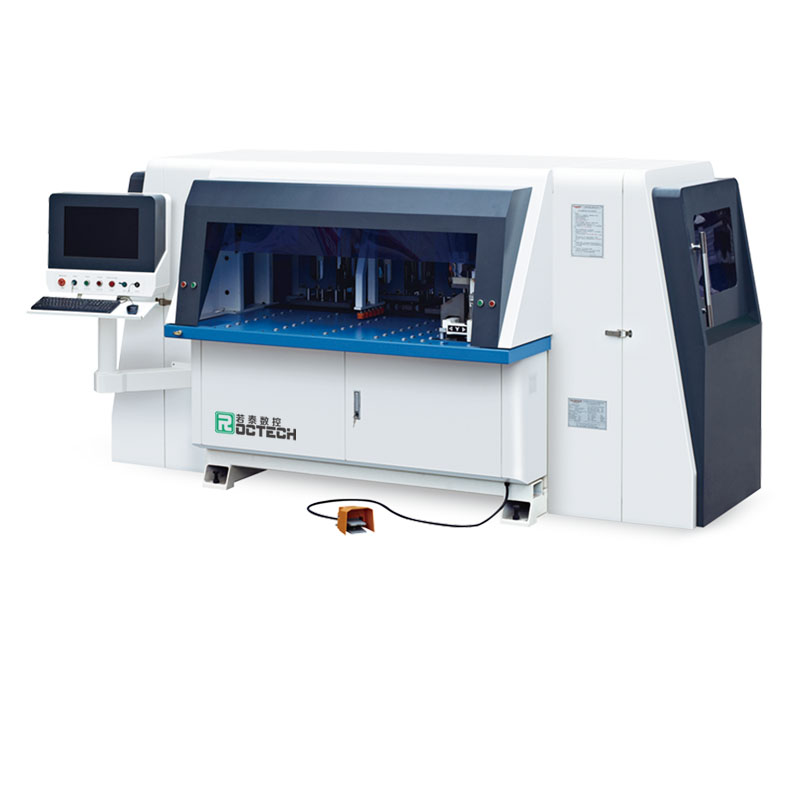

Spindle Power | 2.2KW |

Max width of panel | 50mm |

Mini Length of Panel | 1200mm |

Mini Length of Panel | 200mm |

Max Thickness of Panel | 50mm |

Vetrical Boring Unit | 7(X-Axis)+10(Y-Axis) |

Horizontal Boring Unit | 2+2+2+2 |

Spindle Power | 2.2KW 4800RPM |

Max Speed | X-Axis-70m/min Y-Axis-60m/min Z-Axis-30m/min U-Axis-25m/min |

Working Table Height | 890mm |

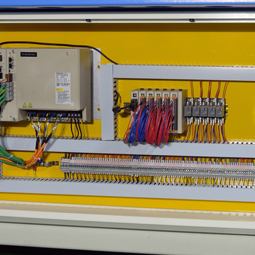

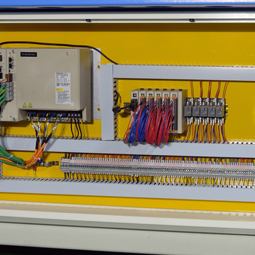

Working Voltage | AC380v,50/60Hz,3Ph |

Working Pressure | 0.6-0.8Mpa |

Total Power | 8KW |

Spindle Power | 18000RPM |

Gross Weight | 2700KG |

Dimensions | 3250*2200*1750mm |